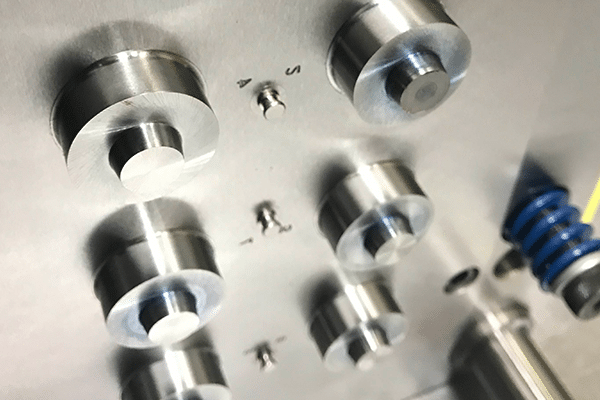

Tooling Design & Manufacturing

National Molding offers full consulting and rapid response contract engineering services which deliver a strategic market advantage to our customers. We can advise on the most efficient and effective tool strategy for your product and production needs for new tooling or for expedited tool transfers. In addition to traditional Custom Molding, we also offer our proprietary Hetero-Cavity® System which if applicable can greatly reduce your tooling costs and dramatically shorten the time from concept to market.

Deep Tool Knowledge

Vertically integrated with internal mold-base manufacturing capability, our deep tool knowledge serves as a key differentiator, enabling quality, custom service, and fast execution. Processes we use to serve you include:

- Mold flow analysis

- 3D Mold and Product design

- PTC Creo systems

- Autodesk Moldflow

- Siemens NX systems

- CNC machining centers

- EDM machining

- Laser welding

- RJG™ Master Molding Initiatives – An essential participant centered training program

Highly Skilled Professionals

Each of our manufacturing plants have highly skilled professionals:

- Industrial Designers

- Engineers

- Program Managers

- Mold Makers

- Mold Maintenance Departments

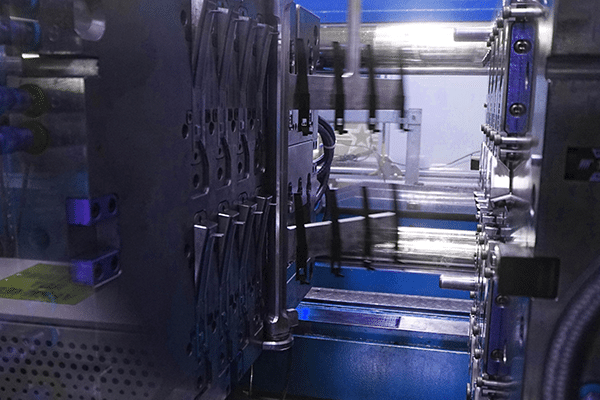

Diverse Range of Injection Molding Capabilities

Our mold designers and makers are highly skilled in designing and producing various types of plastic injection molds:

- Over-molds

- Insert molds

- Modular molds

- Vertical molds

- Horizontal molds

- 2-shot molds

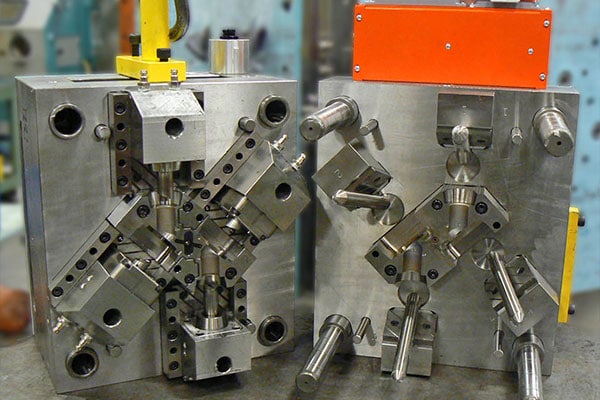

Tool Transfer

Achieve mold transfers with ease with our tool transfer operations. We understand sometimes that you need to switch production locations due to failing suppliers, logistics, plant closures, etc. We specialize in transfers and have the inhouse processes, program management, and tool expertise to make the transition smooth and painless for you. If you have a tool transfer need contact us to give you a part price and explain how we will manage the process for you to take the risk out of your supply chain!

TOOL TRANSFER – Achieve mold transfers with ease with our tool transfer operations. Our procedures follow all necessary steps required to ensure a smooth transition and no supply interruptions for your operations.

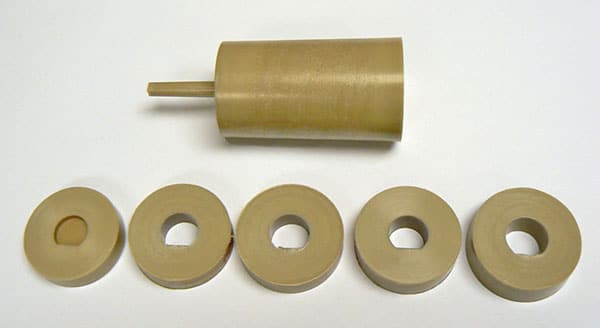

Proof of Concept Service - "Blank" Molds

Development/Prototype Mold Capability

- In-House (Toronto)

- Strategic Partners (Germany, China in development)

Various sizes available

- Allows for concept development/review

- Early MTP investigation

- Limited validation

- Machine to desired size

- Alternative resins can be run