Low Cost Modular Molding

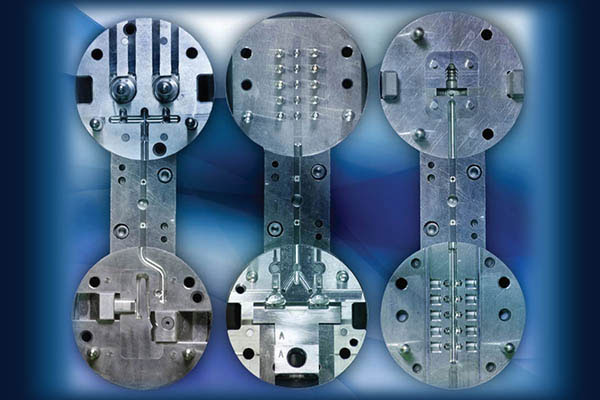

NMC’s Hetero-Cavity® System, a modular molding system produces small, high quality precise parts with low tooling investment and extremely competitive piece pricing.

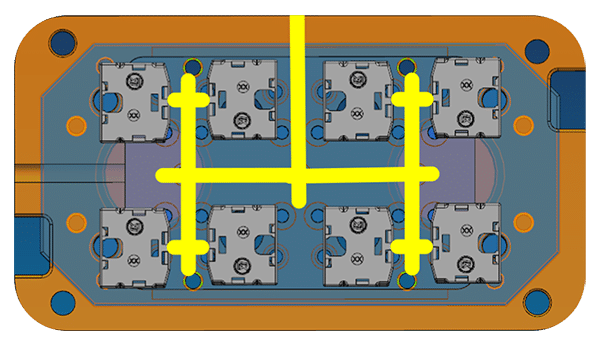

Hetero-Cavity System

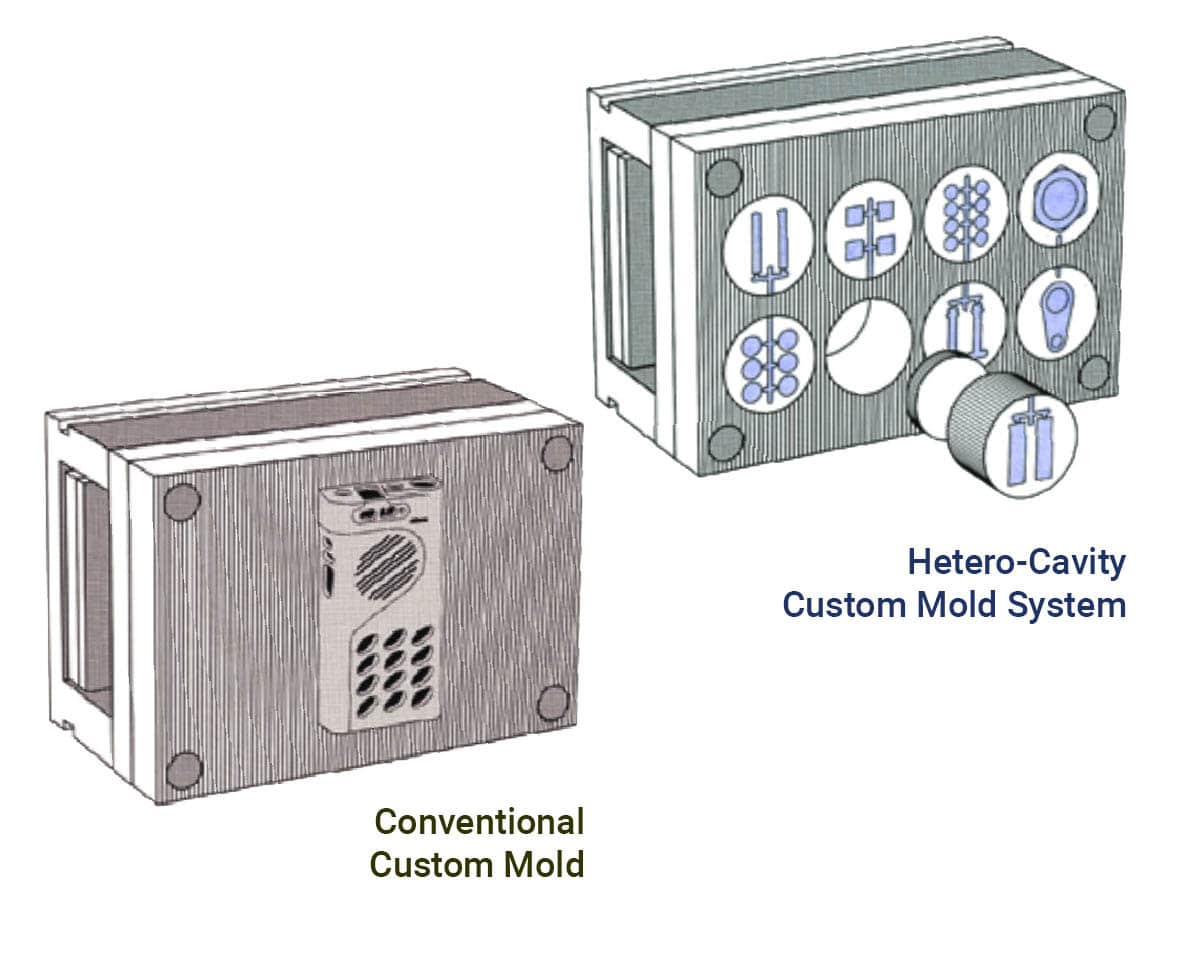

National Molding’s proprietary Hetero-Cavity System utilizes a unique interchangeable, multi-cavity, modular molding system. Tools can have multiple cavities depending on the size of the parts. Different parts can run simultaneously in one machine utilizing our generic mold base and our automated part separation systems, transferring parts directly into their own containers.

Advantages of Hetero-Cavity Moulding

- Tooling costs approximately 1/3rd of custom tools

- Lower unit pricing – machine time spread across multiple parts and customers

- Scalable production–start with one tool and add duplicates as volume requirements increase

- Shorter production order lead times–quick tool changes done in minutes

- Large variety of materials offered

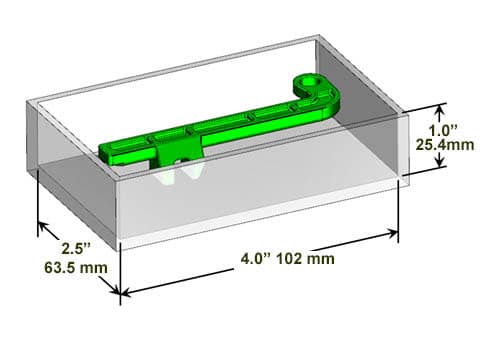

Hetero Cavity - Part Size

Each tool can have multiple cavities depending on the size of the parters.

|

|

|

As a general rule of thumb, Hetero is a good solution for any part that fits inside of this box illustration. |

Different parts can run simultaneously in one machine utilizing automated part separation systems, transferring parts directly into their own containers. |

| Dim Range | Total Tolerance Range | Dim Range | Total Tolerance Range |

|---|---|---|---|

| Inches | Millimeter | ||

| .000 to .250 | 0.003 | 0 to 6.0 | 0.08 |

| .250 to .500 | 0.004 | 6.0 to 12.7 | 0.12 |

| .500 to .750 | 0.005 | 12.7 to 19.0 | 0.15 |

| .750 to 1.00 | 0.006 | 19.0 to 25.0 | 0.18 |

| 1.00 to 1.50 | 0.008 | 25.0 to 38.0 | 0.2 |

| 1.50 and above | 0.010 > | 38.0 > | 0.25 > |

Hetero Cavity Molding Parameters

- A wide variety of molding resins are available

- Maximum shot weight: 18 grams

- Maximum projected area: 4.50 Sq. in.

- Maximum part size: SEE DIAGRAM ABOVE

- Tunnel gate Required

- Print tolerances suited for Hetero required

- Recommended Wall Stock: From .040″ to .120″ Thick

- 25% resin regrind will be in use

- Our typical cavitation: 1, 2, 4, or 8 cavities (dependent on actual part size and EAU)

- Maximum ejector stroke: 1.40″