Pre & Post Molding Services

Each NMC facility offers an array of pre and post molding services. Post molding services include conditioning, testing, assembly, and special packing either manually or with automation, depending on the customer need and the volumes.

Value Added Services

NMC is your partner for secondary operations including the following processes:

- Post-Mold assembly

- Value Add Assembly

- Contract Packaging

- Adhesive Bonding

- Spin Welding

- Ultrasonic Welding

- Thermo Sealing

- Heat Staking

- Thermoforming

Specialized Environment

Some engineered plastic parts require special environments during the manufacturing process.

Some of our specialized process environments we provide:

- Filling in Class 8 clean room

- Climate Controlled Environment

- Annealing: both air and oil

- Climate Controlled Packing

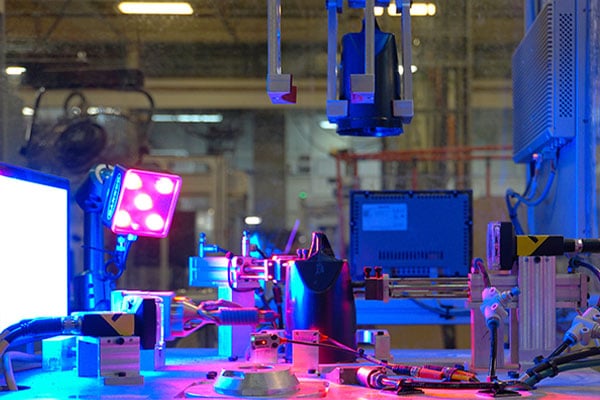

Automation

We utilize robotic automation to support injection molding and post-molding processes. Our experienced automation personnel develop robotic systems which can:

- Reduce cycle times

- Utilize vision systems to ensure quality

- Incorporate additional assembly

- Incorporate packaging processes

These systems are maintained around the clock by a dedicated and knowledgeable team.

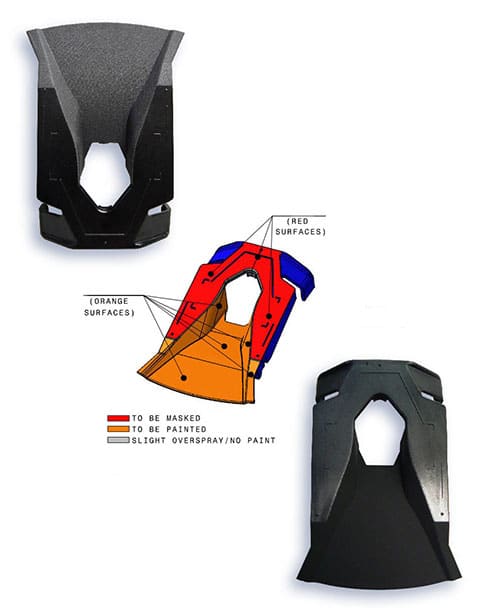

Post Molding Printing

We can also accommodate parts which require more than the engraving capabilities of a molding process. Some of the customizable printing services we can provide include:

- Rotational Pad Printing (syringe barrels) Corona treatment

- Hot Stamping

- Pad Printing

- Laser marking

If your part needs supplement operations, we are your perfect one-stop provider.

Case Study: Diagnostic Kit Filling

Customer Challenge

- COVID kit new market launch

- Optimal filling volume

- Aggressive launch

- Maintain competitive pricing for emerging markets

Technical Solution

- Provided rapid DOE fill volumes for clinical optimization

- Managed launch inventory during FDA approval process

Outcome

- Successfully launched on time, providing market position advantage

- Ensured stock levels to minimize risk of backorder